Training Mode

Implementation of in-house corporate training. Course content is customized according to needs, delivered at your specified location, saving time and travel expenses.

Target Audience

Corporate EHS Managers/Supervisors, Safety Managers, Operations Managers, Plant Managers, Production Managers, Production Supervisors, Technology/Engineering Managers, Engineers, etc.

Course Background

EHS (Environment, Health, and Safety) plays an increasingly important role in modern enterprises. Enhancing the professional skills of EHS-related personnel can effectively ensure the stable and safe operation of the enterprise.

Although VOCs treatment is the final stage of the production line, it is one of the key factors determining whether an enterprise can operate normally and in compliance. Do the EHS-related departments and responsible personnel encounter the following issues in their daily work?

-

Can the current VOCs organic waste gas treatment equipment meet the requirements for compliant discharge?

-

Current VOCs emissions are non-compliant, requiring an upgrade. What process should be chosen?

-

The operational principles of the current VOC waste gas treatment equipment are unclear. How to adjust the operating parameters?

-

The maintenance personnel for the current VOC waste gas treatment equipment are not professional, unable to ensure normal equipment operation?

-

How to solve existing fault problems with the current VOCs organic waste gas treatment equipment, and how to determine spare parts?

-

The operational cost of the current VOCs organic waste gas treatment equipment is relatively high. How to achieve energy conservation and consumption reduction?

-

Do potential safety hazards exist in the current VOCs organic waste gas treatment equipment? Is a HAZOP analysis necessary?

If you face any of the above issues, we can conduct targeted research on the existing VOCs waste gas treatment equipment within your enterprise, addressing the relevant problems. We also provide professional theoretical training for your operational staff to enhance equipment operation and maintenance skills, reduce the probability of equipment failure, optimize operating parameters, and lower energy consumption.

Course Benefits

-

Understand concepts, sources, emission standards, safety risks, etc., related to VOCs treatment.

-

Understand technologies related to VOCs treatment: Technical principles, advantages, and disadvantages of RTO, RCO/CO, Zeolite Rotor + RTO/CO, Activated Carbon Adsorption & Concentration + CO, etc.

-

Understand the operational principles and energy consumption analysis of key equipment related to VOCs treatment technologies: RTO, RCO/CO, Zeolite Rotor + RTO/CO, Activated Carbon Adsorption & Concentration + CO, etc.

-

Understand common faults and maintenance key points of key equipment related to VOCs treatment technologies: RTO, RCO/CO, Zeolite Rotor + RTO/CO, Activated Carbon Adsorption & Concentration + CO, etc.

-

Analyze fire and explosion safety risks and emergency plans related to VOCs treatment technologies: RTO, RCO/CO, Zeolite Rotor + RTO/CO, Activated Carbon Adsorption & Concentration + CO, etc.

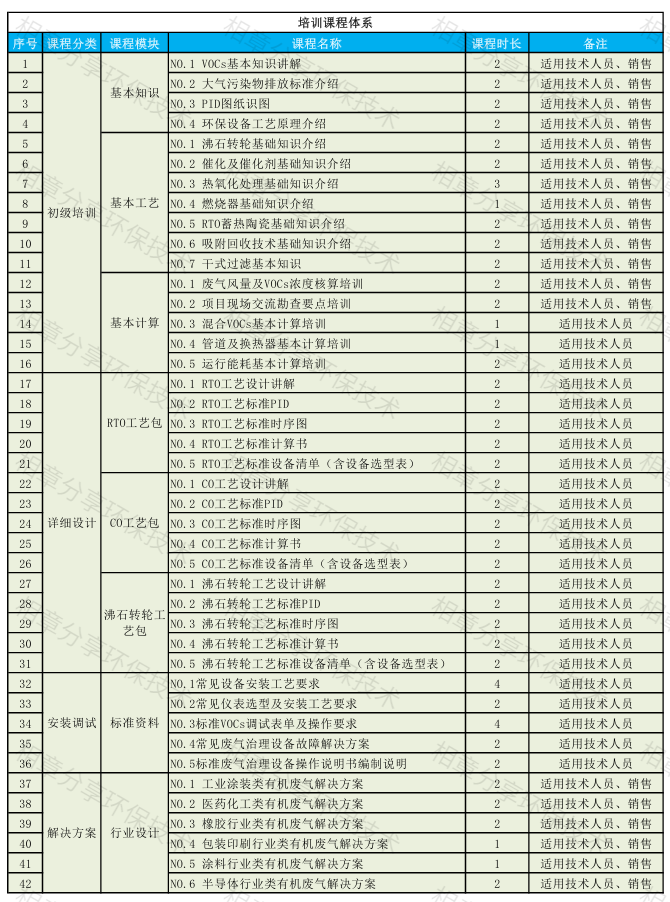

Course System Catalog

(Content section not detailed in the original text)

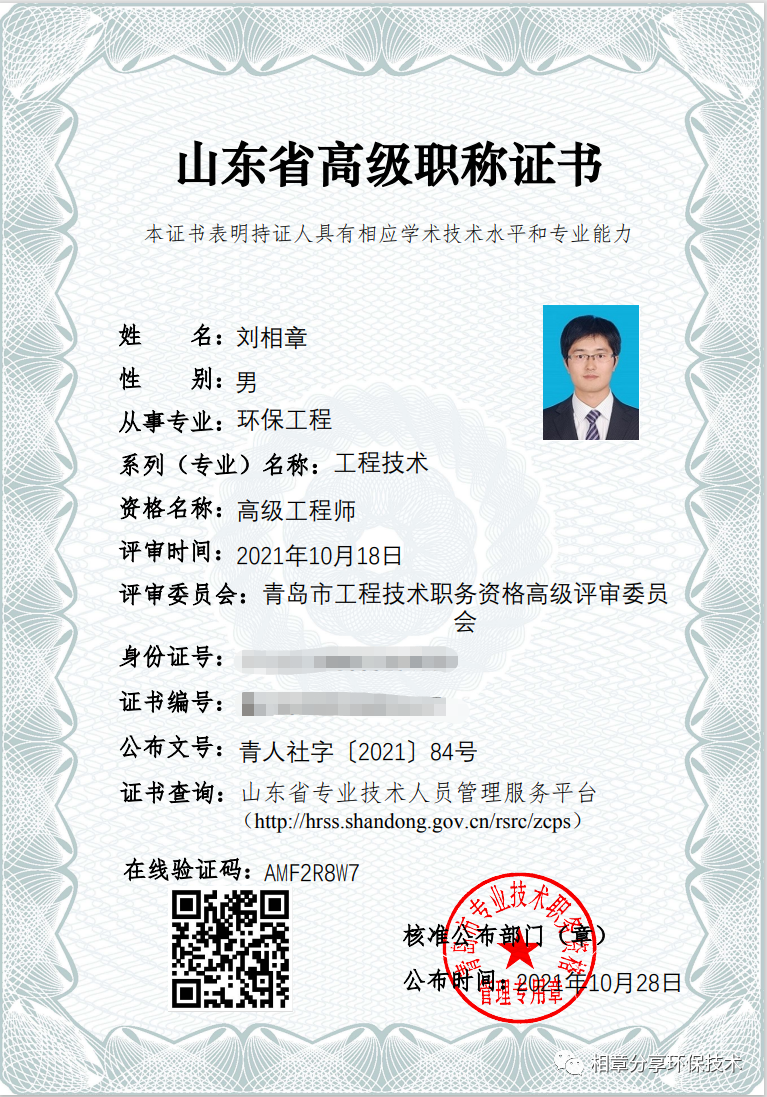

Instructor Introduction

Trainer: Liu Xiangzhang

Graduated from China University of Petroleum (Beijing) with a Master’s degree. Senior Environmental Engineering Engineer.

Worked at Qingdao Huashijie Environmental Protection Technology Co., Ltd. from 2013 to 2022, accumulating ten years of design and management experience in the VOCs organic waste gas treatment industry. Successively held positions including Process Design Engineer, Process Design Manager, Head of Process Design Department, Chief Process Technology Engineer of the Technical Center, Responsible Person for Process Standardization in the Technical Center, Pre-sales Technical Department Manager, etc.

Contact Us (Contact Me)

Contact Person: 185-6136-9976 (same number for WeChat)